Røros Museum, Copper Foundry

The second part of the Røros Museum is a real metallurgical workshop, where copper smelting began in 1646.

The painting above the entrance depicts what the factory looked like in 1888.

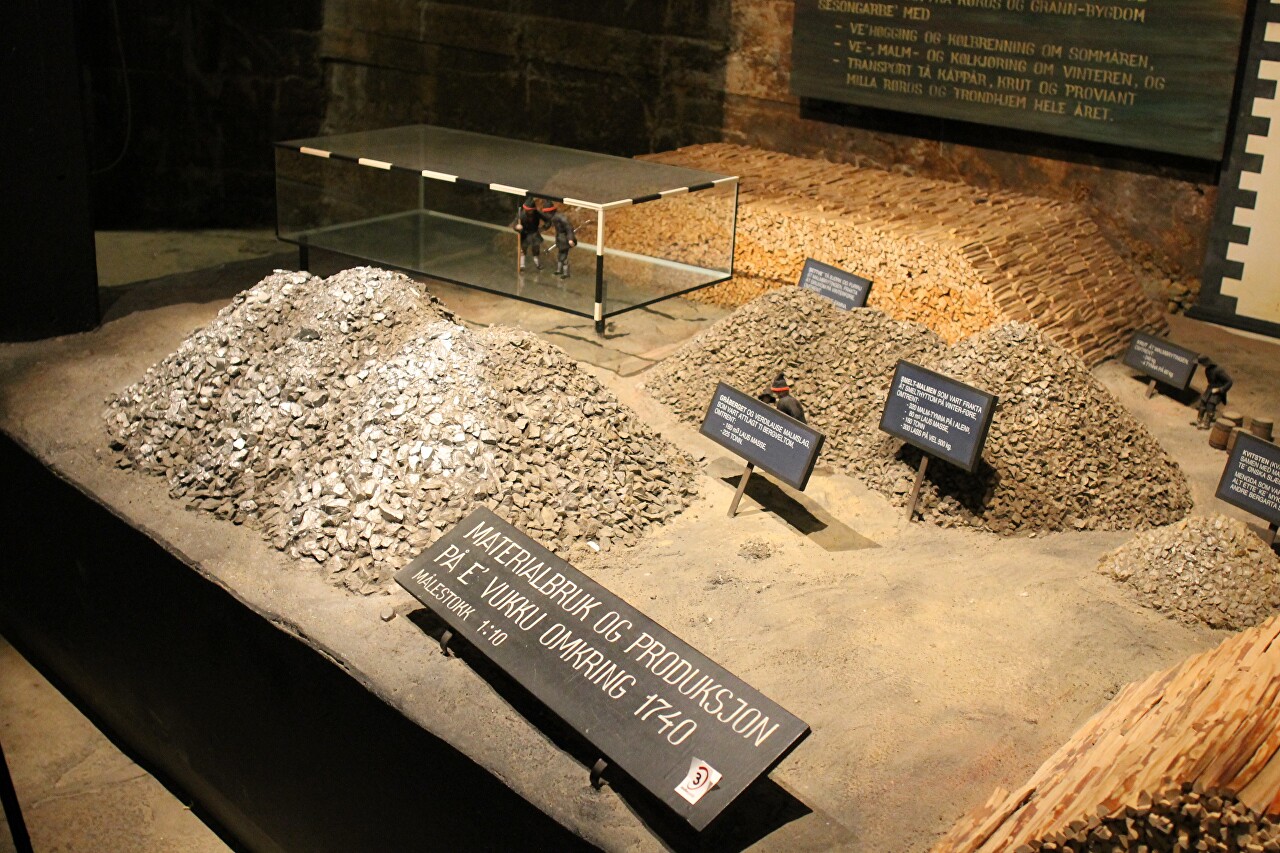

The models clearly demonstrate how the process of copper smelting took place in the 17th and 18th centuries.

From the mine, copper ore was delivered to the charge yard of the smelter.

In addition to the ore, quartz was also stored here, with the help of which iron was removed from the melt.

Fuel was firewood, which was harvested in the surrounding forests.

All transport operations were done manually, with workers delivering materials to the furnaces on stretchers.

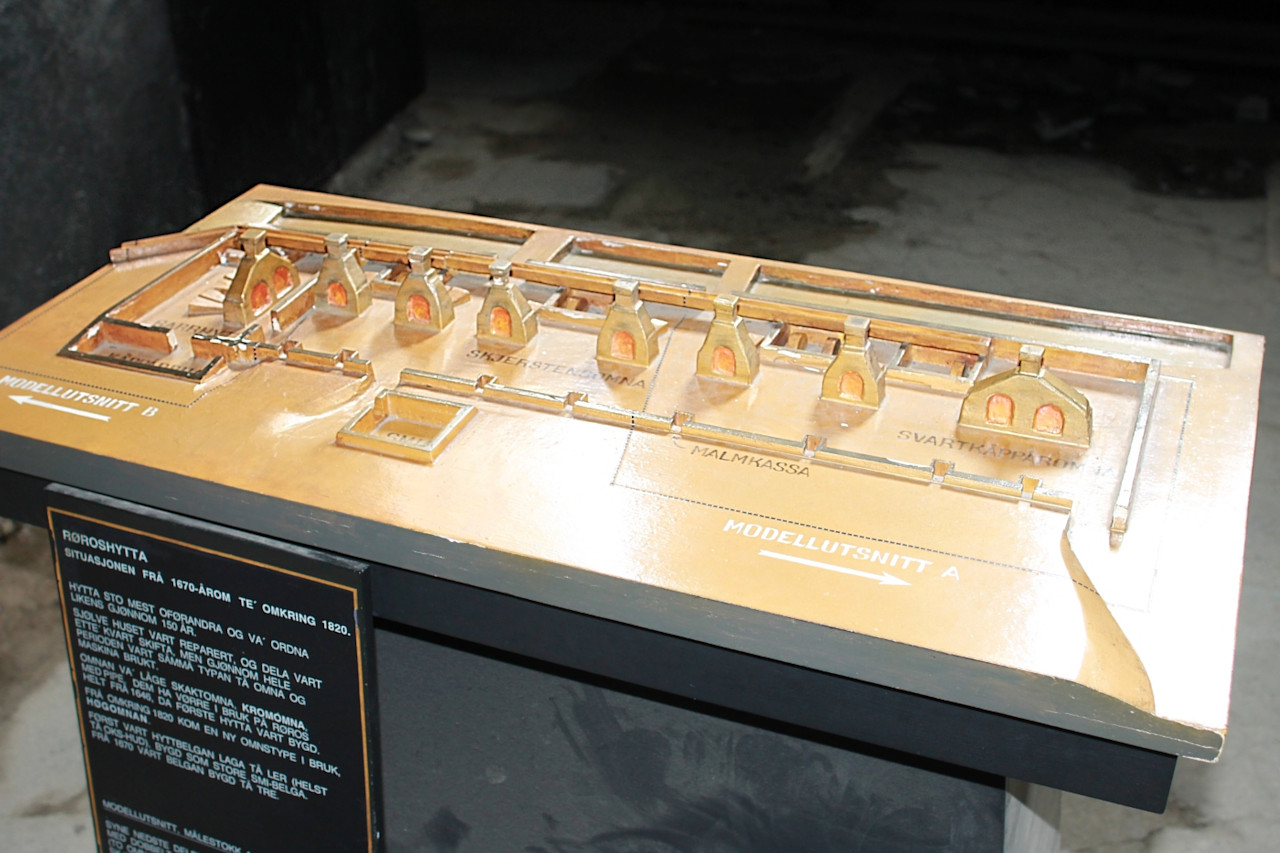

Melting furnaces were located along the river, which served as a source of energy for driving mechanisms.

Cross-sectional layout of the foundry. To the left of the furnace is a blacksmith's bellow, above it a box-tray for water supply.

A dam was built on the river, from where water was fed through wooden trays to the impellers.

The wheels were turned by crank mechanisms that drove the bellows that pumped air into the smelting furnaces.

Carefully made models of the mechanisms completely repeat the technology of that time and are now rotated by water.

Melting furnaces were built from natural layered stone.

Loading the charge into the furnace.

Exhaust ports of the furnace. Light slag drained through the upper one, heavy copper came out through the lower one.

The main tool of the metallurgist is a wheelbarrow and a shovel. It would seem that the work is not tricky, but in order to get high-quality metal, it was necessary to know very precisely when and how much to add to the furnace the materials needed for melting.

Metal and slag were drained into cast-iron bucket carts, the slag was taken to landfills, and mtall was sent for bottling.

A small metallurgical laboratory is located in the corner of the shop, where the quality of copper was evaluated, and now souvenir ingots are smelted.

The form is a rectangle.

These ladles were used to pour molten metal into molds.

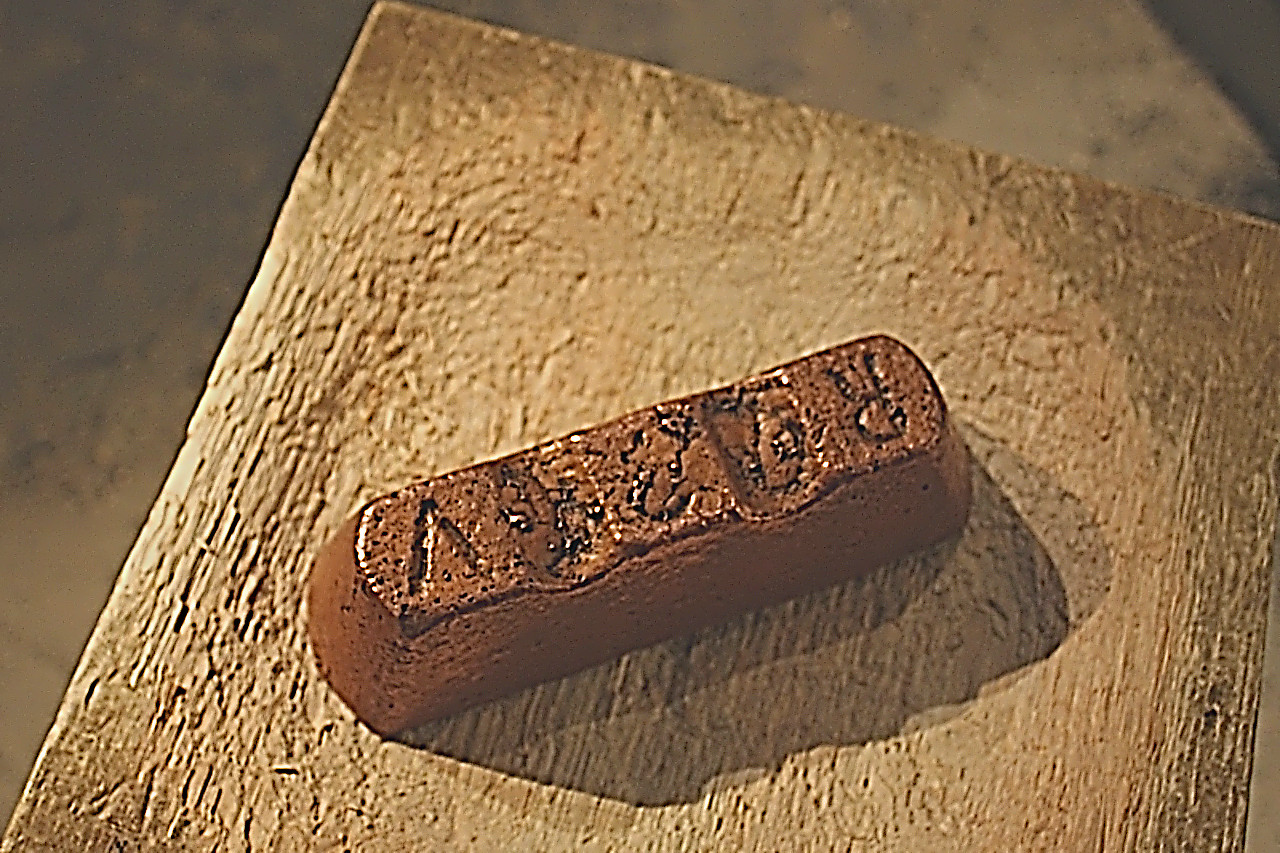

Copper was sent to buyers in the form of such ingots.

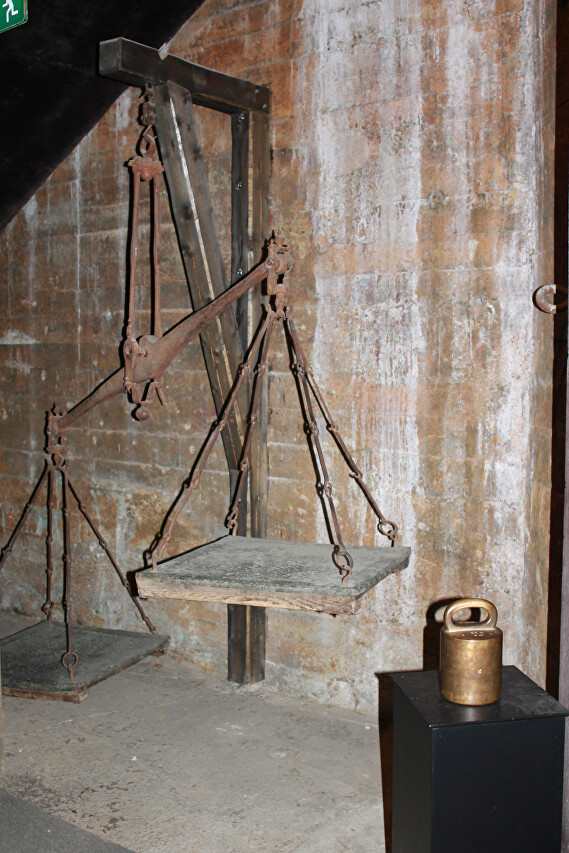

The products were weighed and carefully accounted for-copper was a very expensive commodity. Cannons and church bells were poured from it, and sheets were rolled to cover roofs, which in some places have been standing for 300 years.

Over time, wooden trestles were replaced with concrete ones, and air was supplied from electric superchargers through iron pipes instead of blacksmith bellows.

Mechanical boot devices were introduced.

I myself worked in a copper smelter, and I want to say that at my enterprise there is little different from what I saw here. Approximately the same way in modern furnaces is arranged a place for the release of metal.

The company operated until 1953. Now only the bases with niches for ladles, where metal and slag were drained, remain from the furnaces.

Pieces of frozen metal taken out of stopped furnaces.

The graphs show the company's performance indicators for more than three centuries.

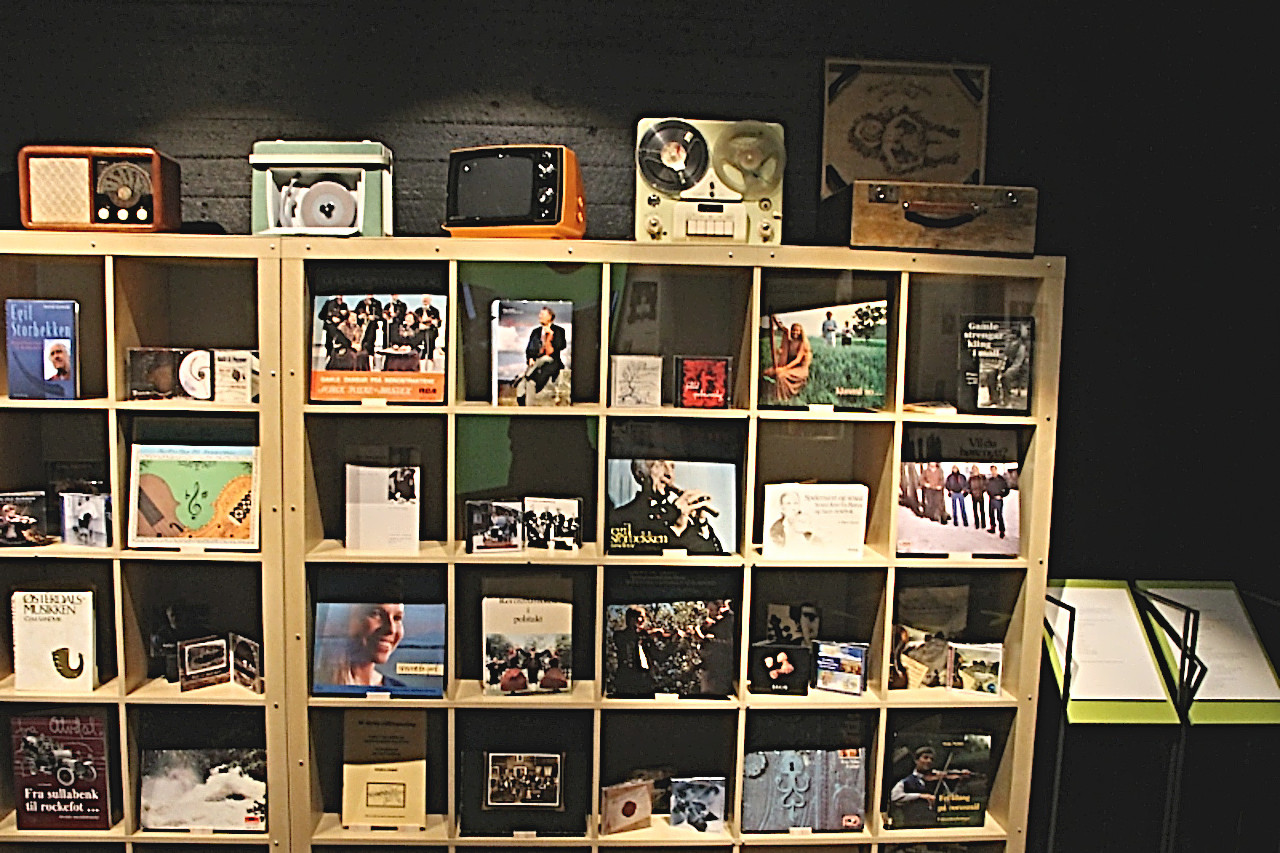

In the lobby of the museum there is a small collection of everyday objects of miners and metallurgists.