Old Photos of the Røros Copper Foundry

The Røros Museum of Metallurgy and Mining has several unique photographs of the late nineteenth century, from which you can get information about the technology and working conditions of that time. Copper smelting was carried out in so-called shaft furnaces. Copper ore was lifted up the trestle, then loaded into the furnace along with fuel (charcoal, later coke). air was supplied to the lower part of the furnace, keeping the fuel burning. Bellows for blowing were driven by water wheels. Production in Røros passed the era of steam, as by this time the surrounding forests had long been cut down and turned to charcoal, so here they immediately switched from water wheels to electric drive.

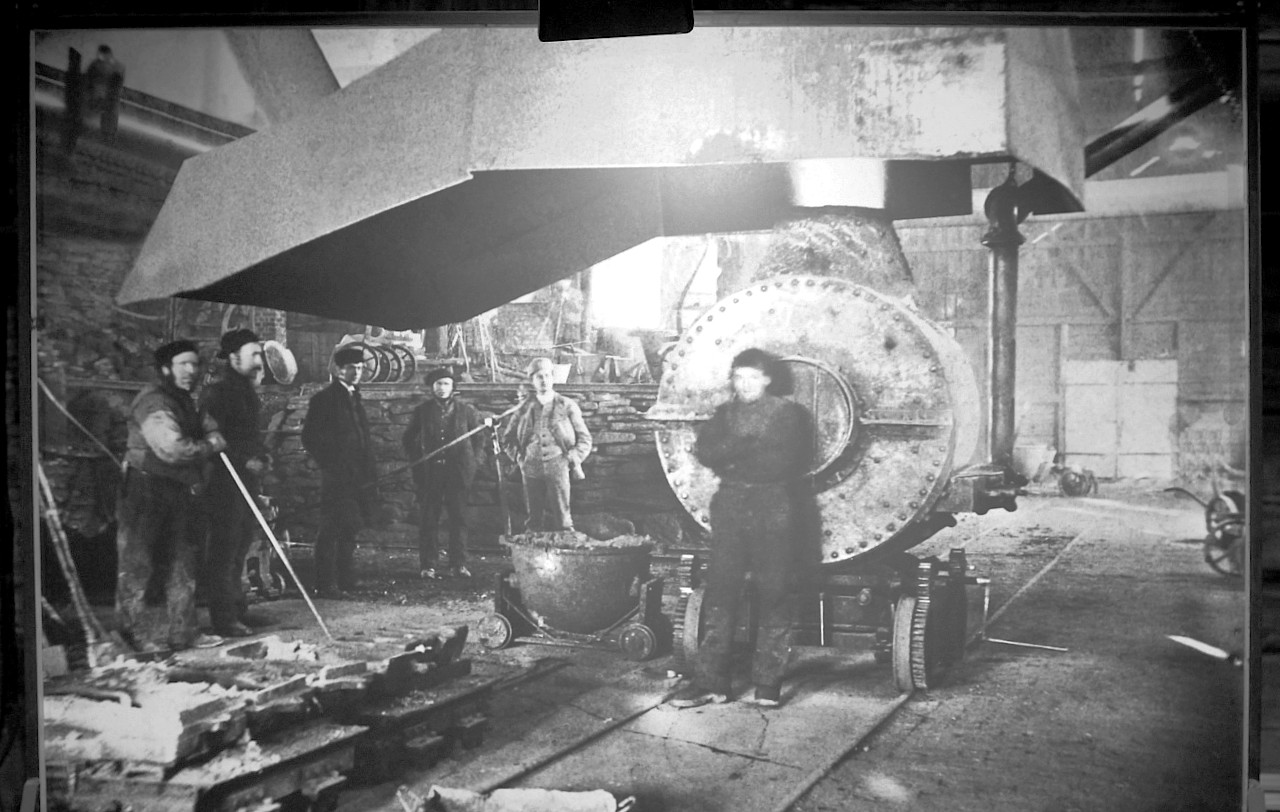

Copper spill site. A round barrel on rails is a mixer where the melt of the desired composition was obtained. Approximately the same technology is still used in some places today. Above the filling area, you can see an exhaust duct for removing smoke and gases. As you can see, even in those days, some measures were taken to improve working conditions.

The workers did not have any special protective clothing. Protection from high temperatures and sparks of molten metal were jackets made of thick cloth. Of course, there was no respiratory protection, so the life of the copper factory workers was short. In the photo, mostly very young guys. I have worked in metallurgy for more than 20 years, and I can imagine what it is. When

I first came to the copper smelter in 1992, the equipment and tools of

the then metallurgists were not much different from what we see in this

photo. Now,

of course, everything is much better with labor protection, but even

with modern personal protective equipment and special clothing, the work

of a metallurgist remains difficult and dangerous.